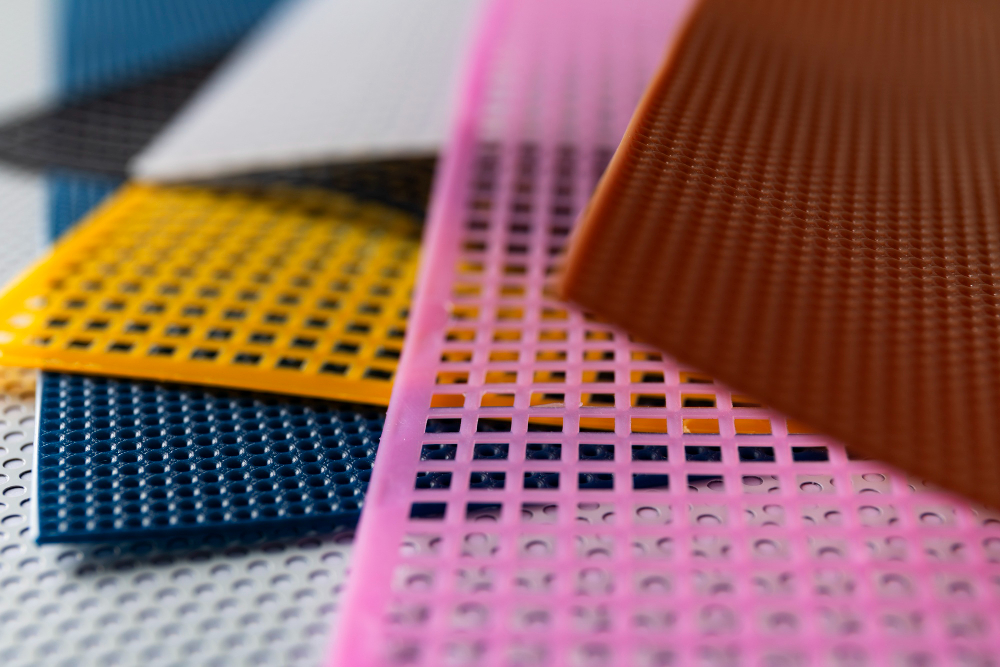

Silicone molds are versatile gear that has become increasingly famous in diverse industries, from baking and cooking to crafting and manufacturing. These molds provide a range of benefits because of their flexibility, sturdiness, and simplicity of use. This article explores the exclusive aspects of silicone molds, which include their advantages, programs, and tips for proper use.

![]()

Understanding Silicone Molds

Silicone molds are made from silicone rubber, a fabric regarded for its flexibility and sturdiness. Silicone is a synthetic polymer that remains solid at high and occasional temperatures, making it ideal to be used in molds. Unlike conventional molds made from metal or plastic, silicone mold can without difficulty release the items they form without requiring extra lubrication or non-stick sprays.

The primary gain of silicone molds is their non-stick floor. This characteristic allows for the smooth removal of baked goods, crafts, or castings, decreasing the chance of breakage and ensuring that objects keep their intended shape. Additionally, silicone molds can withstand severe temperatures, so they can be utilized in both the oven and the freezer.

Another benefit of silicone molds is their flexibility. Unlike rigid molds, silicone molds can be bent or folded without changing their shape, allowing for easy storage and dealing with. This flexibility additionally makes it less complicated to launch gadgets from the mildew without compromising their form.

Applications of Silicone Molds

Silicone molds are utilized in numerous programs across specific industries. In the culinary international, they’re popular for baking and cooking because of their non-stick homes and warmth resistance. Silicone molds come in various sizes and styles, such as trays for truffles, cakes, and chocolates, in addition to specialized molds for difficult designs and decorations.

In addition to their culinary makes use, silicone molds are also applied within the crafting industry. Crafters use silicone mold to create custom gadgets together with resin rings, cleaning soap, and candles. The flexibility of silicone allows for certain complicated designs, making it a preferred fabric for intricate craft tasks.

Furthermore, silicone mold has packages in manufacturing and business settings. They are used to supply custom elements and components in a variety of substances, such as metals, plastics, and composites. The ability to create specific and consistent shapes makes silicone mold precious for generating first-rate merchandise in diverse industries.

Advantages of Using Silicone Molds

Silicone molds provide several advantages over traditional molding substances, including steel and plastic. One of the number one advantages is their non-stick surface, which gets rid of the want for added release dealers and makes cleanup less difficult. This non-stick property is in particular beneficial in baking, where it guarantees that baked items release effortlessly from the mildew.

Another benefit of silicone mold is its temperature resistance. Silicone can withstand temperatures starting from -forty°F to 450°F, permitting it to be used in both the oven and the freezer. This versatility permits users to create items that require different temperature situations without switching molds.

Tips for Using Silicone Molds Effectively

To make the maximum of silicone molds, it is crucial to follow certain recommendations and high-quality practices. First, it’s miles vital to nicely preheat the oven or freezer earlier than using silicone mold. This ensures that the mold reaches the preferred temperature for the most excellent consequences.

When the usage of silicone molds for baking, it’s miles useful to area the mildew on a baking sheet for delivered balance. Silicone molds are bendy, and setting them on a baking sheet helps save you from spills and guarantees even cooking.

After use, permit the silicone mold to chill before attempting to do away with gadgets or ease the mildew. This save you warping or harm to the mold. Cleaning silicone molds is simple, as they may be washed with heat, or soapy water or located in the dishwasher. Avoid using abrasive scrubbers, as they can harm the mildew’s floor.

For crafting functions, make sure that the silicone mold is completely easy and free from any residues before use with materials like resin or cleaning soap. Properly curing or setting the material in the mold in step with the producer’s instructions will yield great consequences.

The Future of Silicone Molds in Various Industries

The use of silicone mold is probably to continue growing in diverse industries because of its numerous blessings. In the culinary field, innovations in mildew designs and programs will enhance the flexibility of silicone molds, taking into consideration even greater creative and complex baking and cooking techniques. Advances in silicone mold technology will also improve the precision and best of craft items.

In production and commercial applications, silicone molds will play a vital position in producing super components and merchandise. Their capacity to create tricky shapes and withstand harsh conditions makes them precious for industries that require unique and durable molds.

Conclusion

Silicone molds provide a range of benefits that make them a precious device in various industries. Their non-stick surface, temperature resistance, flexibility, and sturdiness set them aside from traditional molding substances. Whether used for baking, crafting, or production, silicone molds offer a sensible and efficient solution for creating extremely good gadgets.

As silicone mold technology keeps adapting, we can expect even greater opportunities and innovations of their use throughout distinctive fields.

FAQs

1. Can silicone mold be used in both the oven and freezer?

A. Yes, silicone molds are quite versatile and might resist temperatures ranging from -forty°F to 450°F. This makes them appropriate to be used in both the oven and the freezer, taking into consideration a wide range of applications.